Patents – Lincoln Paving Products Inc.

Innovative Engineering Inside Every Casing

At Lincoln Paving Products, we don’t just build windrow elevators—we’ve patented the technology that makes them perform better.

Our REMIX AUGER (U.S. Patent #6,481,922 B2) and MATERIAL MODIFIER (U.S. Patent #7,785,033 B2) are engineered to eliminate asphalt segregation and ensure a uniform, high-quality mix every time. Housed within our proprietary casing design, these patented systems work together to re-blend, fragment, and homogenize Hot Mix Asphalt (HMA) or rubberized asphalt—so your paving job runs smoother from start to finish.

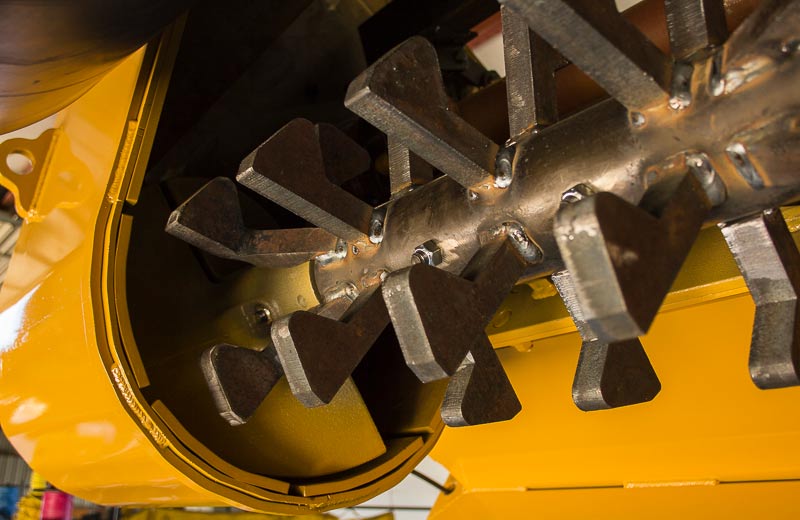

REMIX AUGER

US Patent # 6,481,922 B2

November 19, 2002

An apparatus and method for re-mixing size and weight-segregated Hot Mix Asphalt (HMA) continually discharges from a windrow elevator. The auger assembly's 1st and 2nd helical auger sections are mounted to converging, opposite-handedness. Their orientation advances incoming material inward, toward the mixing zone, adjacent to and around an intermediate portion of the connecting shaft. Drive devices rotate the assembly so large pieces of material are continuously advanced inwardly and commingled with small pieces delivered to the mixing zone.

MATERIAL MODIFIER

US Patent # 7,785,033 B2

August 31, 2010

An auger and tine assembly with a common drive shaft, designed to fragment and re-mix agglomerated pieces of Hot Mix Asphalt (HMA) or rubberized asphalt before application to the road surface. The drive shaft features a rotating tine section and a corresponding interdigitated fixed tine section, positioned between our patented augers. As the material passes through the apertures formed by the fixed and rotating tines, agglomerated chunks are broken apart and thoroughly re-mixed, resulting in a consistently homogeneous mix ready for immediate use by the asphalt paving machine.